How Augmented Reality Can Improve Upkeep and Remote Assistance Easier

Table of Contents

Admit it or not, we are approaching the fourth industrial revolution. Conservative businesses on the outside of development are cautious of the advances being made by technology. Conversely, the revolutionary players who have embarked on innovative technologies such as Augmented Reality Remote maintenance and repair assistance is driving the transformation from the front. Equipment maintenance and upkeep is one of the most frequent services in the manufacturing business and this expense usually surpass 30% of total operating expenses. Conventional industrial equipment repairs and maintenance are often performed on-site by qualified workers, whereas complicated machinery necessitates professionals traveling to the site of the equipment. The procedure is costly and time-consuming, and it has a detrimental influence on production.

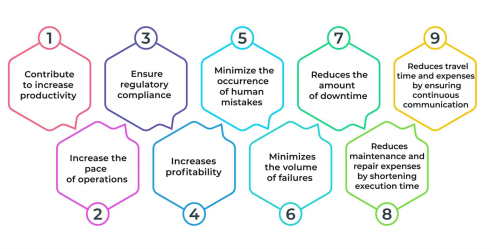

Now, let's look at the advantages of AR remote assistance:

Also Read: How can it be crucial for Equipment Manufacturers to use the Remote Assistance Platform in the post-COVID world? AR-enabled systems may assure preventative maintenance by offering operator assembly instructions, documentation on new procedures, and a regulatory checklist. By enhancing productivity panels and getting authentic access to data for processing and assessment of interruptions, predictive maintenance is ensured. AR in Maintenance In the industrial business, upkeep plays an important role. Since its initial roots, the sector has evolved dramatically. Previously, equipment was much slower and control methods were much simpler. Customers were not as demanding, and system failures were not as severe. It is a whole different scenario right now. Maintenance has an impact on 3P key aspects of organizational effectiveness: productivity, pricing, and performance. Operators typically depend on a comprehensive checklist to optimize preventative maintenance of pieces of equipment. It is easy to conduct inspections and manage inventories using AR-backed solutions.

AR in Augmented Reality

Difficult and complicated machinery requires the assistance of highly experienced specialists for maintenance and repairs. Because it is impractical to always have access to specialists and in all locations. AR remote assistance facilitates the delivery of specialist expertise regardless of geographical location. Service technicians may now use their AR remote help app to interact with specialists utilizing smart glasses or headgear to achieve a faster assessment and problem resolution. It helps to save time and money while also minimizing downtime. Furthermore, organizations may benefit from enhanced quality control, shared knowledge, lower costs, and increased production efficiency along the assembly line. Another significant advantage of adopting AR technology into your organization is its potential to encourage more fluid communication across all teams involved.

Conclusion:

Organizations are collaborating with technology partners to create a revolutionary remote assistance software that can increase efficiency and productivity significantly. Another very essential benefit of working in augmented reality remote assistance is increased productivity and better customer service. Maintenance and repair are only a few of the numerous advantages of augmented reality technology. While we continue to learn more about this technological powerhouse. We are confident that the future of augmented reality will bring many new and helpful developments. With a thorough grasp of AR technology, please contact us if you believe your business is ready to take the next step toward increased productivity.